PRODUCTS

HZL-F400

Exceed Quilt & Pro

Sewing Evolution EXCEED Series in Stitch Quality and Sewing Specifications.

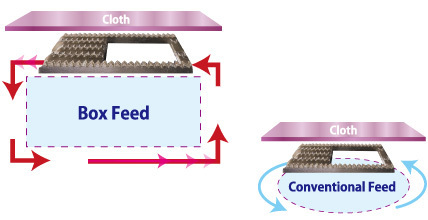

Box Feed - Industrial Sewing Machine Technology

In order to provide beautiful seams and outstanding feed performance, JUKI adopted box feed system. The conventional feed mechanism is oval motion. On the other hand, the box feed moves the feed dog in a box motion. This eliminates material shrinking and shifting. This accurate feeding system provides superior stitch quality for a variety of light to heavy weight fabrics.

As the feed dog is in contact with the material longer, the machine feeds the project better.

No fabric shrinkage even sewing on extra light weight materials.

Thick handle can be sewn with ease.

Powerful Feeding

HZL-F series has powerful feeding thanks to a special steel feed dog and improved presser foot construction. Heavy material projects, such as hemming denim jeans, can be sewn with ease!

3-12-3 layers of denim.

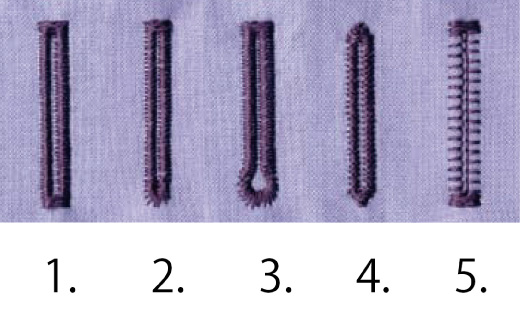

Industrial Quality Buttonholes【NEW】

Using a unique sensor method, HZL-F series sews beautiful buttonholes regardless of the type of material and overlapped sections.

16 types of buttonholes are available for your needs.

1. Standard, 2. Rounded end, 3. Keyhole, 4. For knit,

5. Decorative

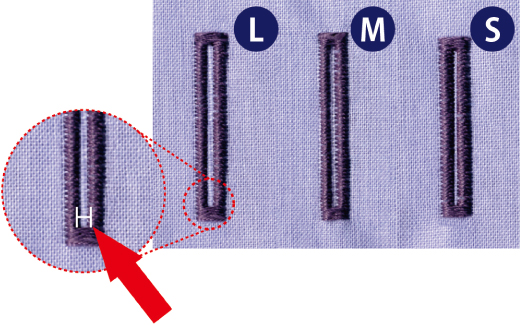

Cutting Width Adjustment of the buttonhole!!

Now it is possible to adjust the cutting width in 3 steps.

Foot Controller with Thread Trimming Function【NEW】

HZL-F series trims both needle and bobbin threads automatically by pressing the heel side of the foot controller. With this feature you can concentrate on your project while automatically cutting the thread.

Direct Stitch Pattern Selection

Frequently used stitch patterns can be selected directly through the Direct Select mode.

Piecing

Zigzag stitch for applique

*Open toe presser foot is an option.

Accessory Parts for Machine Quilting (Standard)

Walking Foot

Quilt Presser Foot

Patchwork Presser Foot

Other Features

Automatic Needle Threader

Needle can be threaded quickly and easily.

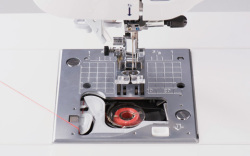

Quick Bobbin Preparation

Just follow the guide and it is not necessary to pull up the bobbin thread.

Easy Bobbin Thread Winding

Independent motor winds the bobbin thread. The bobbin preparation is easy.

Presser Foot Pressure Adjustment

Presser foot pressure can be adjusted for better sewing results according to the type of materials to be sewn.

Knee-lifting Lever

Presser foot can be raised and lowered by the knee-lifting lever. Presser foot lift is up to 12 mm when the lever is used.

タブコンテンツ2(オレンジ線下から)

SPEC / ACCESSORIES

| Control system(Arm size) | Computer (Arm Size 203㎜) |

| Dimensions | 445(W) x 291(H) x 210(D)mm |

| Weight | 9.8kg (21.6LBS) |

| Maximum sewing speed | 900 sti/min |

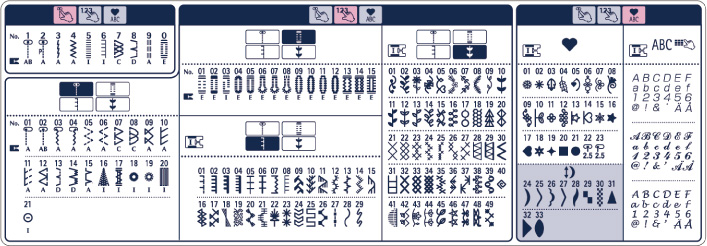

| Number of stitch patterns | 157 and Alphabetic/numeric fonts:3 |

| Buttonhole | Automatic (sensor system) with clamping plate Cutting width adjustment Buttonhole Length: 0.7 - 3.2cm |

| Direct stitch pattern selection | 〇 |

| Start/stop button | Green: Ready to start and/or while sewing Red: Not ready to start |

| Adjustable starting / reverse stitch speed | - |

| Auto thread trimming | 〇 |

| Thread cutter | 〇 |

| Automatic needle threader | One hand |

| Thread tension system | Automatic |

| Needle up/down button | 〇 |

| Low-speed inching sewing | - |

| Needle stop position | Down |

| Needle stop position switching | 〇 |

| Lock stitch | Reverse stitch (Button system) Reinforcement stitch pattern Automatic lock stitch and thread trimming |

| Feed mechanism | 7 point feed dog BOX Feed |

| JUKI Smart Feed (dual feed function) | - |

| Presser foot pressure adjustment | Stepless adjustment |

| Auto presser foot lift system |

| Micro-lifter | - |

| Function to straight-line stitching | Throat plate for straight stitch (option) |

| Presser foot pivot function | - |

| Presser foot lift (1 step/2 steps) | Lever system: 5.5mm / 12mm |

| Horizontal presser foot holder button | 〇 |

| Drop feed | 〇 |

| Quick bobbin preparation | 〇 |

| Easy bobbin winding (Bobbin winder with independent motor) | 〇 |

| Bobbin thread detection | - |

| Stitch length | Button system / LCD numerical display Max. 5mm |

| Stitch width | Button system / LCD numerical display Max. 7mm |

| Number of needle position (straight stitch/other than straight stitch) | 37 / - |

| Pattern reverse | left/right |

| Twin needle sewing | 〇 |

| Lock mode | - |

| Elongation | 〇 |

| Save/call of patterns | 10 patterns |

| Light | 1 LED light |

| Type of hook | Horizontal hook |

| Free arm | 〇 |

| Cord reel | - |

| Knee lifting lever | 〇 |

| Foot controller | with thread trimming function |

| Wide table | Option |

| Accessory storage | Auxiliary bed/ accessories bag |

| Sewing machine cover | Hard case with accessory storage part |

| Operation support | DVD Operation guide |

| Supported languages | spec_light8lang |

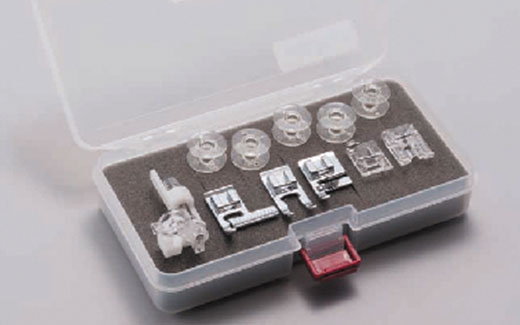

| Accessories (presser feet) | Standard presser foot (A) Zipper presser foot (B) Overcasting presser foot (C) Blind stitch presser foot (D) Buttonhole presser foot (E) Manual buttonhole presser foot (I) Walking foot (N) Patchwork presser foot (P) Quilt presser foot (Q) |

| Other accessories_1 | Bobbin (4) Needle set HA X 1 #11(1):#14(1):#16(1):for knit #11(1) Twin needle Quilt guide Auxiliary spool pin T-shape screwdriver Ripper/Cleaning brush/Spool cap (large) Spool cap (middle) Spool cap (small) Foot controller Knee-lifting lever Power cord Hard case Instruction manual Operation support DVD |

| Other accessories_2 |

INCLUDED ACCESSORIES

Standard Presser Foot

It can be used to sew lightweight to heavyweight materials.The wide needle entry opening allows this presser foot to be used for a variety of fabrics and applications, from straight stitches to zigzag stitches.Press the black button to keep the presser foot horizontal in order to smoothly begin sewing at a thick seam.

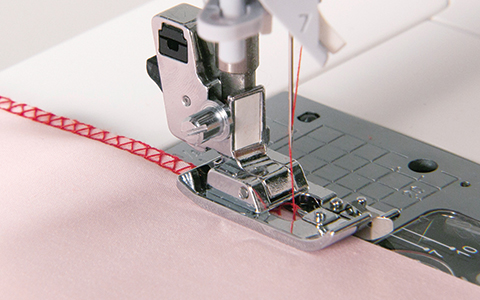

Overcasting Presser Foot (Overedge Foot)

Sew with the edges of the fabric aligned with the guide. The prong in the opening of the presser foot presses down the edge of the fabric to prevent puckering. In addition, the amount of thread going into the stitching is adjusted by the thread crossing the prong, creating a clean finish with little shrinkage. This presser foot cannot be used to sew zigzag stitches or overcasting by 3-point zigzag.

Buttonhole Presser Foot

You can sew buttonholes of the appropriate size by simply placing the button in the button holder of the presser foot.

Decorate Stitch Presser Foot (Manual BH Presser Foot/Satin Stitch Foot)

The groove along the bottom of this presser foot ensures that the presser foot does not catch on the stitching, ensuring the fabric will be smoothly fed. Use to accurately sew a buttonhole near a thick seam that is hard to reach. Also Used to Manually Create Oversize Buttonholes.

Blind Stitch Presser Foot (Blind Hem Foot)

By sewing with the fabric fold aligned on the guide of this presser foot,only a few threads of the fabric will be uniformly caught in the stitch. Adjust the needle entry point before sewing. You can also use this presser foot as a guide when changing the needle position for hemstitching in a straight line.

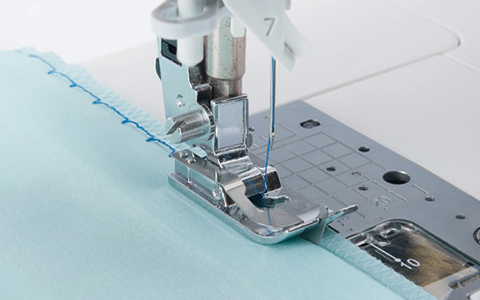

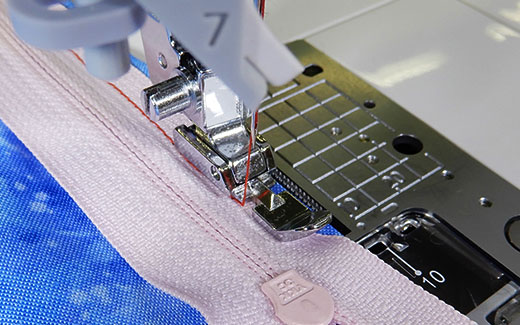

Walking Foot

This presser foot is equipped with an upper feed dog that works together with the feed dog of the sewing machine to feed the material in order to prevent bunched stitching and uneven feeding. By inserting the quilt guide bar, this presser foot can be used to quilt equally spaced seams.

Patchwork Presser Foot

Always ensure needle is set to center straight stitch. Align the edge of the fabric with the outer presser foot guide for a seam allowance of 1/4" or with the inner presser foot guide for a seam allowance of 1/8". There are also marks at a 1/4" spacing at the front and back of the presser foot, allowing you to see the width of the seam allowance before and after needle entry.(Normal type and for JUKI Smart Feed.)

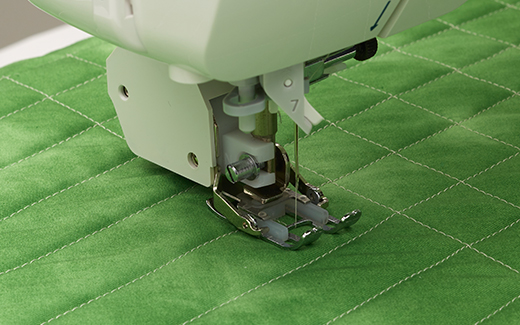

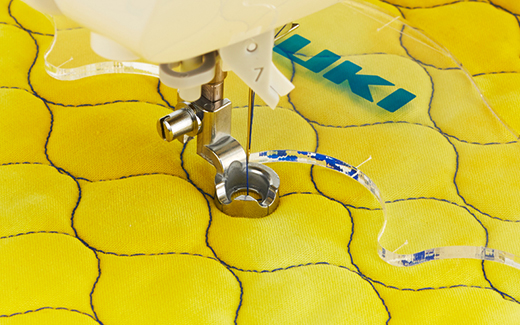

Quilt Presser Foot

With the feed dogs lowered, you can freely move the fabric to draw using stitching. Use the screw to adjust the height of the presser foot according to the thickness of the fabric, so the fabric moves smoothly.

Quilt Guide

Insert this guide into the hole of the presser foot holder or the walking foot, and then sew while lightly tracing this guide along stitching. Adjust the spacing of the stitching by changing how far this guide is inserted. You can use this guide inserting from either the right side or the left side.

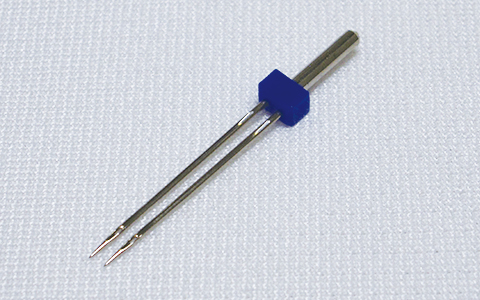

Twin Needle

For beautiful decorative stitches two threads can be a perfect addition. Also it is used for sewing pintucks with the pintuck feet. Set the sewing machines with 2 needle settings with optional functions. Not all stiches are approved for twin needle design.

Auxiliary Spool Pin (Additional Spool Pin)

Use this spool pin with a thread spool for twin needle sewing, spare machine threading or bobbin winding.

Foot Controller with Foot Switch Function

Controlling the sewing machine with your foot leaves both of your hands free while sewing. You can trim threads and or do another operations by pressing on the another switch of the foot controller.

Knee-lifting Lever

Using your knee to push the lever to the right raises the presser foot,and when you return it will lower the presser foot.

Bobbin(1pc)

Since the bobbin type differs depending on your sewing machine model,be sure to use the bobbin designed for your machine.

OPTIONAL ACCESSORIES

Button Attaching Presser Foot

Be sure to first lower the feed dog so the fabric is not fed and adjust the zigzag width so the needle enters the holes in the button. To create a shank for the button, insert an awl or another similar object into the groove in the presser foot before sewing on the button so that the stitching will create a loop suitable for the thickness of the fabric.

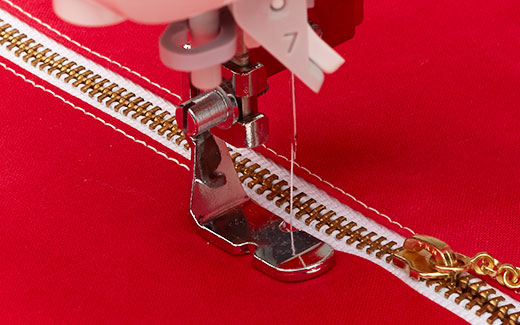

Adjustable Zipper Foot

The position of the adjustable zipper presser foot can be changed over to the right and left of the needle to allow the sewing machine to sew the material while avoiding its thicker part such as a zipper.

Narrow Zipper Foot

Since the width of the narrow zipper foot is small, the operator can easily observe the material during sewing. It has two (right and left)recesses on its undersurface, you can sew higher portions of the material while avoiding those portions. Both the right and left sides of the zipper can be sewn only by changing the position of the needle base line. The mounting portion of this presser foot is placed at its center, so the stable feed of the material is ensured.

Invisible Zipper Foot

Since this presser foot lifts the teeth of the zipper as they are fed through the groove along the bottom of the presser foot, you can closely sew along the edges of the zipper teeth.

Smooth Presser Foot

This presser foot, made of a fluorocarbon resin, smoothly feeds even vinyl-coated material and leather fabrics which may stick to a standard presser foot and are difficult to sew.

Roller Foot

The rollers at the front and back of this presser foot prevent it from sticking to or bunching fabrics for perfect seams.

Rolled Hemming Presser Foot

The spiral guide of this presser foot rolls the edge of the fabric to create a narrow rolled hem. This presser foot can be used on light-weight to medium-weight fabric. Since the fabric can be uniformly folded twice without ironing, this presser foot is useful for finishing ruffles and handkerchief edges.

Hemming Presser Foot for Zigzag

The spiral guide of this presser foot rolls the edge of the fabric while the narrow rolled hem is sewn with a zigzag stitch. This presser foot can sew thin and solid edging.

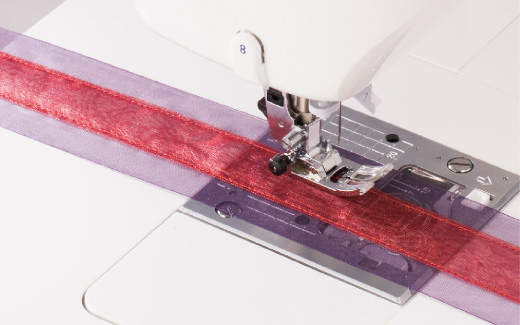

Binder Presser Foot

After tape with a width of about 0.75" to 1.0" (22 to 25 mm) is passed through the guide, this presser foot creates double-fold tape with a width of about 0.2" (5 mm) and sews it to bind the fabric. Single-fold tape with a width of about 0.4" to 0.5"(10 to 13 mm) can also be used. You can move the guide to the left or right to adjust the needle entry point.

Pintuck Foot Narrow

When sewing pintucks in parallel, the 9 slits on the bottom of the presser foot can be used as a guide. Pintucks are suited to light-weight soft materials. Pintucks of stable shape can be produced while putting a cord in each pintuck.

Pintuck Foot Wide

When sewing pintucks in parallel, the 7 slits on the bottom of the presser foot can be used as a guide. Pintucks are suited to light-weight soft materials. Pintucks of stable shape can be produced while putting a cord in each pintuck.

1/4“ Guide Foot

Always ensure needle is set to center straight stitch. Align the edge of the fabric with the presser foot guide to easily sew with a seam allowance of 1/4" (6.4 mm). Since the needle drops into a small round opening, the seam is stabilized to create a perfect straight stitch.

Presser Foot with Guide

On the right side of the presser foot, there are guidelines at a 2 mm spacing from 0 to 2 cm from the center of the needle entry opening (center needle position). This presser foot is useful when sewing parallel straight or decorative stitching.

Ditch Sewing Presser Foot (Edge Sewing Presser Foot)

The long guide at the center of the presser foot fits perfectly in the seam line to stabilize stitching. You can also use this presser foot as a guide when changing the needle position for hemstitching in a straight line.(Normal type )

Compact Guide Edge Sewing Foot

This presser foot has a shorter guide at its center. With this shorter guide, smoother feed of the material is promised. Furthermore, it is expected to reduce uneven material feed. The marks on the left side of the presser foot will be the guide for the outline quilting. By changing the needle base line, you can sew the single lap stitching with ease.

Quilt Presser Foot (for Ruler)

With a distance of 1/4" (6.5 mm) from the needle entry point to the outer edge of the presser foot, sew using a ruler as a guide. The front of the presser foot is lowered, making it easier to see the needle area. Adjust the height of the presser foot according to the thickness of the fabric.

Quilt Presser Foot (Open Type)

Use the screw to adjust the height of the presser foot according to the thickness of the fabric, so the fabric moves smoothly.

Quilt Presser Foot (Zigzag Type)

The wide needle entry opening allows this presser foot to be used for free-motion sewing with zigzag stitches. Since the presser foot moves up and down together with the movement of the needle, thick seams can easily be crossed.

Open Toe Presser Foot

The wide opening at the front of this presser foot makes appliques and designs easy to see, which is useful for curvy decorative stitching. The groove along the bottom of this presser foot ensures that the presser foot does not catch on the stitching, so the fabric will be smoothly fed.

Applique Presser Foot

Since the front and back of this presser foot are short and transparent, appliqu?s and designs are easy to see, and you can easily sew sharp curves. The pin at the back keeps the presser foot horizontal, stabilizing it even when sewing appliqu?s.

Pearl Attaching Presser Foot

Pass the strand of pearls or beads up to a diameter of 4 mm through the dome-shaped groove in the center of the presser foot, and then sew with a zigzag stitch. This presser foot can also be used for sewing on thick cording, braiding or piping cord, even on curves.

Fringe Foot

This foot has a claw at its center. It is used for forming loops by laying the thread over the claw. This presser foot can be used for sewing decorative stitches on workpieces by making three-dimensional thread loops and fringes on the edge of the fabric with your favorite threads.

Cording and Embroidery Presser Foot

This presser foot has a hole for supplying cording to be sewn over. With the feed dog lowered, you can freely move the fabric to create simple embroidery with cording.

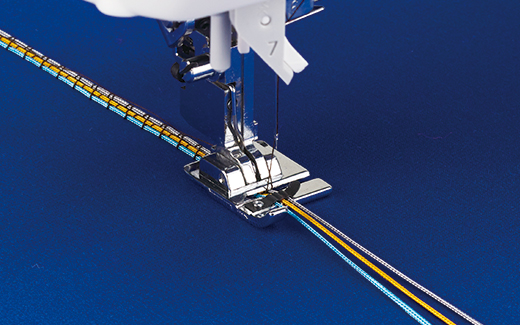

Cording Presser Foot (for 3 Cords)

Pass threads through the three channels in front of the needle entry opening and sew them with the three-point zigzag stitch or decorative stitches in order to create three-dimensional decorations.

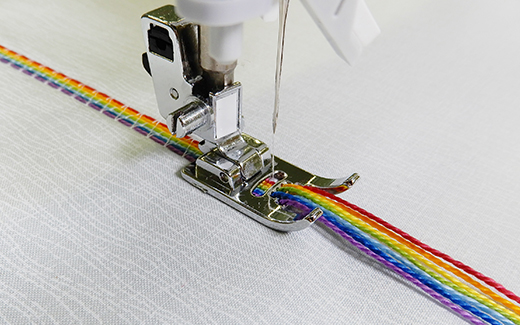

7 Hole Cording Foot

This presser foot is provided with seven cord insertion holes of approximately 1 mm in diameter. As many as seven (1 to 7) thin cord(s) or embroidery thread(s) can be sewn using these holes while neatly arranging them in parallel (in the case of two or more cords / threads are used).

Gathering Foot

Change the stitch length, thread tension and presser foot pressure to adjust the amount of fabric that is gathered. You can also use this presser foot to sew two pieces of fabric together while creating gathers in only the lower piece.

Dedicated Hook for Thick Thread Decoration

Wrap the thread you want to decorate around the bobbin and draw a pattern with pattern stitching or free motion.

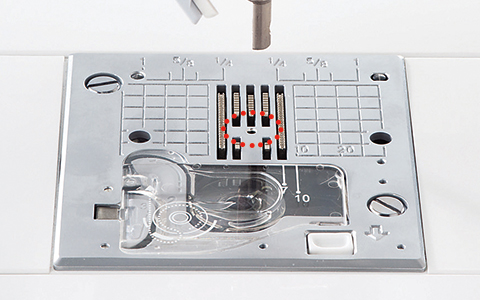

Throat Plate for Straight Stitch

This needle plate is used to sew the straight stitch with the center needle position. Creates perfect needle feed for light weight fabrics or corner to corner stitching in patchwork piecing. HZL-G210/G110 Part No. 40080968 & 40064685(hook cover)

Magnetic Gauge

A strong magnet holds this gauge in place on the needle plate. This gauge can also be used on household sewing machines with a metal needle plate.

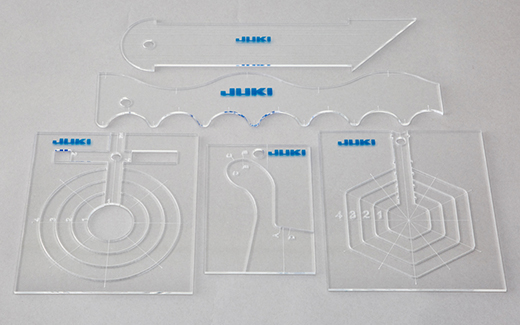

Ruler Kit (HZL type)

Various patterns can be formed by combining basic lines and shapes. This kit contents straight, wave, hexagon, circle, feather shapes. Be sure to use this kit together with the presser foot for ruler. The thickness of these rulers are 3mm.

Wide Table

After removing the auxiliary bed, this table can easily be installed by fitting it into place.

Foot Switch Stopper

Installing this stopper on the foot controller disables the function that is activated by stepping on the controller with your heel.

Advanced Quilter's Kit

This set contains the following: Edge Sewing Presser Foot, Quilt Presser Foot (Open Type), Quilt Presser Foot (Zigzag Type), Open Toe Presser Foot, Applique Presser Foot, Pearl Attaching Presser Foot

Heavy User Kit

This set contains the following: Button Attaching Presser Foot, Invisible Zipper Foot, Rolled Hemming Presser Foot, Binder Presser Foot, Presser Foot with Guide, Cording and Embroidery Presser Foot

Creative Set

This set contains the following: Applique Presser Foot, Cording and Embroidery Presser Foot, Pearl Attaching Presser Foot, Cording Presser Foot (for 3 Cords), Presser Foot with Guide, Open Toe Presser Foot, Bobbin x5

タブコンテンツ3(オレンジ線下から)

STITCH PATTERNS