PRODUCTS

TL-2010Q

1-Needle, Lockstitch, Portable Sewing Machine

with automatic thread trimmer for quilting, tailoring, apparel and home decor

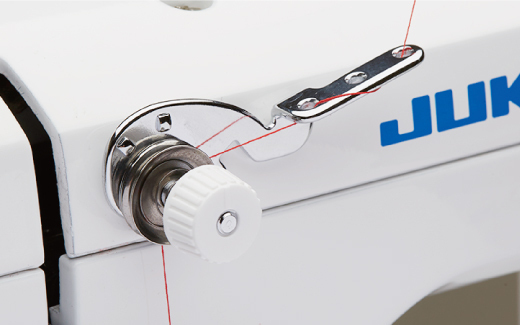

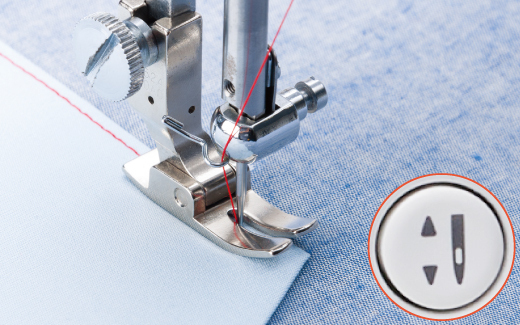

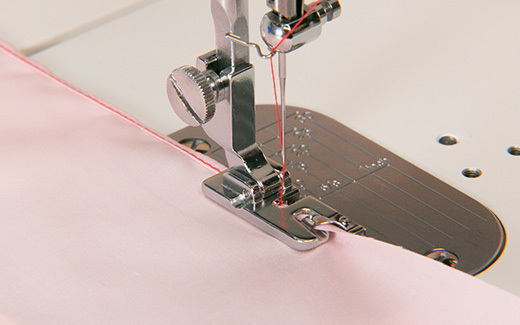

Sub Tension Unit

No matter the thread type, sub-tension ensures stitches are sewn with a balanced thread tension. Achieve Perfectly balanced threads with every stitch.

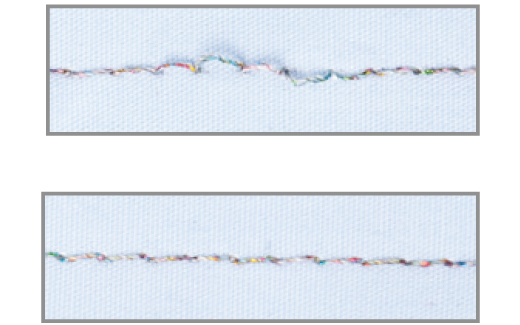

Strongly twisted threads can make for unruly stitches. (above)

Sub-tension creates steady stitches by preventing return of twist of threads. (below)

Maximum Sewing Speed Control

Now you can control Maximum sewing speed within the range from 200 to 1,500 SPM with this slide knob. This is ideal for free motion quilting or when a fixed sewing speed is required for your sewing techniques.

Foot Controller with thread trimming function

It is possible to automatically trim both needle and bobbin threads by pressing the heel side of foot controller. The foot controller is big enough and it is easy to control sewing-start and -stop.

LED Light

LED light brightens the needle area for better material handling.

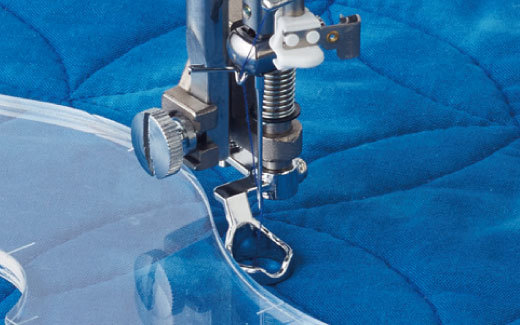

Even Feed Foot

With its reliable feed, the even feed foot ensures the machine's ability to produce beautiful seams when sewing difficult-to-feed fabrics such as georgette and velvet, as well as heavy weight materials such as leather. The even feed foot is ideal for sewing multiple layers of fabric evenly.

Standard Accessory Parts

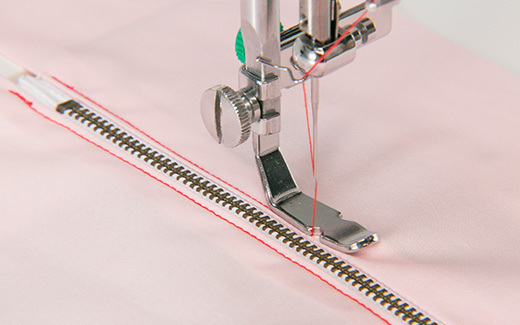

Zipper attaching foot

Even Feed foot

1/4" Quilting foot

Other Features

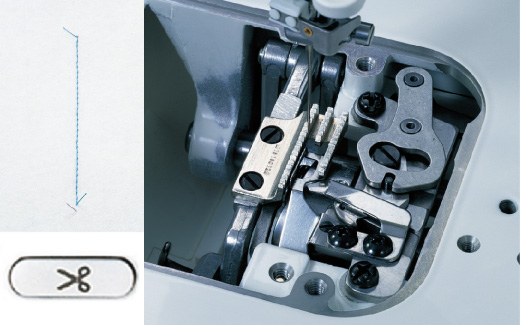

Automatic Thread Trimmer

The machine is equipped with an automatic thread trimming device that simultaneously trims the needle and bobbin threads at the sewing end by lightly pressing the push-button. It uses the thread trimming mechanism that is similar to the industrial sewing machine type, trimming thin through thick threads without fail. Auto thread trimming may also be activated by the foot controller.

Easy Bobbin Replacement

A new bobbin case latch and an enlarged bobbin case area make it easier to remove and replace the bobbin. When the auxiliary table is being utilized, it is equipped with a sliding plate that allows convenient access to remove and load bobbins as well.

Predetermined Stop Position of the Needle

When you stop sewing, the machine will come to an accurate stop with the needle down. To move the needle up or down as desired, simply press the needle up/down button. When the button is pressed continuously, the machine sews stitch by stitch at low speed.

Heavy-Weight Materials are sewn with Ease

The speed control mechanism, operated by microcomputer, allows the machine to sew materials at low speeds. This provides for accurate feed and perfect stitching when sewing heavy weight fabrics, quilting and multiple layers of materials.

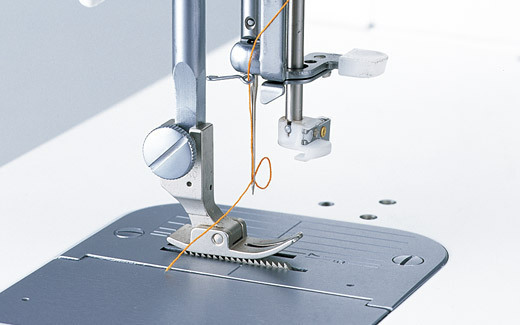

Automatic Needle Threader

The push lever automatic needle threader easily threads the needle without eyestrain and allows you to start sewing quickly.

Adjustment of Presser Foot Pressure

Presser foot pressure can be adjusted according to the fabric being sewn by turning a regulator located on the top of the machine. The pressure amount can then be viewed at a pressure indicator.

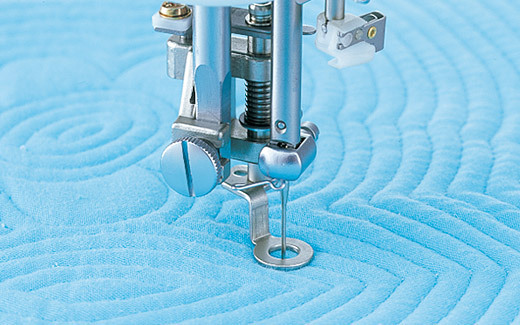

1/4" Quilting Foot / Drop Feed

The quilting foot is designed for free motion quilting and free-hand embroidery. A 1/4" Quilting Foot is supplied as standard accessories with the machine. It is for precision sewing with 1/4" inch stitch width.

The feed dog can be raised and lowered simply by depressing a switch. When quilting, the drop feed allows you to sew curved stitches with ease.

Knee Lifter Lever

The knee lifter lever allows you to lift/lower the presser foot without using your hands. The presser foot can be raised as high as 12mm, so that light to heavy weight materials are easily handled in and out of the sewing area with ease.

Thread Tension Scale

The machine is provided with the thread tension scale, which allows you to adjust the tension according to the thread and material to be used.

Industrial Machine Engineering

The arm and bed of the TL-2010Q are constructed of aluminum die-casting. This tough body lowers vibration while sewing and ensures high quality stitching. Since the TL-2010Q has many industrial sewing machine features, it is possible to attach several types of industrial presser feet. (For more details, please contact the dealer near you.)

The Machine is Light-Weight and Portable

This portable, lightweight machine is easy to transport and can be carried wherever you desire.

Needles

The machine is supplied with HA-type needles, the identical type used with home sewing machines and home sergers. This type of needle cannot be attached incorrectly.

Larger Work Area

The machine has a wider handling area than a conventional sewing machine adding space to maneuver large size materials or rolls of quilting fabric. An auxiliary table is supplied for extending the work area for quilting and larger sewing projects.

タブコンテンツ2(オレンジ線下から)

SPEC / ACCESSORIES

| Dimensions | 452(W) x 350(H) x 219(D)mm |

| Arm size | 215(W) x 150(H)mm 8.5"(W) x 6"(H) |

| Auxiliary table dimensions | 590(W) x 335(D)mm 23"(W) x 13"(D) |

| Dimensions with auxiliary table | 720(W) x 335(D)mm |

| Weight | 11.5kg / 25.4Lb |

| Sewing speed | Min. 55 - Max. 1,500SPM |

| Needle | HA x 1 (130/705H)/ HL x 5 #9-#18 |

| Auto thread trimming | ✓ |

| Thread cutter | ✓ |

| Speed control knob | ✓ |

| Automatic needle threader | ✓ |

| Thread tension dial scale | ✓ |

| Sub tension unit | ✓ |

| Needle stop position | Down |

| Needle up/down &Low-speed inching sewing button | ✓ |

| Drop feed | ✓ |

| Presser foot pressure adjustment | Stepless adjustment |

| Float function(micro-lifter) | - |

| Presser foot lift (1 step/ 2 steps) | By lever 7/9mm, by knee lifter 12mm |

| Stitch length | 0 - 6 mm |

| Light | LED |

| Type of hook | Horizontal-axis Full-rotary Hook |

| Bobbin case | Bobbin case with bobbin hold/removal function by latch |

| Attachment mounting plate | - |

| Foot controller | ✓ with thread trimming function |

| Auxiliary table | ✓ |

| Knee lifting lever | ✓ |

| Accessories (presser feet) |

Standard presser foot Zipper attaching foot Even feed foot 1/4" Quilting foot |

| Other accessories | Bobbins (4) Needles (HAx1) Foot controller Auxiliary table Knee lifter lever Sewing machine cover Power cord Exclusive screwdriver Screwdriver (small) Oiler Spool cap Cleaning brush Instruction manual |

OPTIONAL PARTS

1/4" Quilting Foot (for Ruler)

1/5" Quilting foot

Quilting Foot Side Open Toe

Hemming foot

Compensating presser foot

タブコンテンツ3(オレンジ線下から)

SEWING SAMPLES

Quilt tapestry

Quilt cushion cover

Quilt bed cover