PRODUCTS

MO-735N

2-Needle, 2/3/4/5-Thread Overlock Machine with Cover Stitch and Chain Stitch

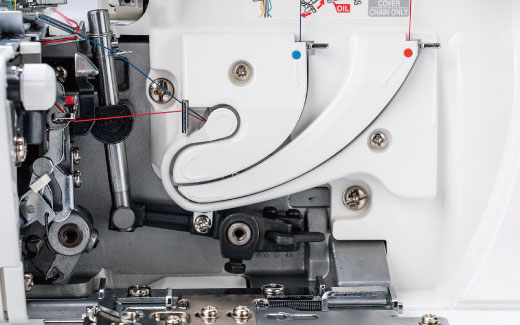

Easily change from overlock to cover stitch!

You can easily switch from overlock to cover stitch.

Overlock settings

Cover stitch settings

Supports all basic stitch patterns

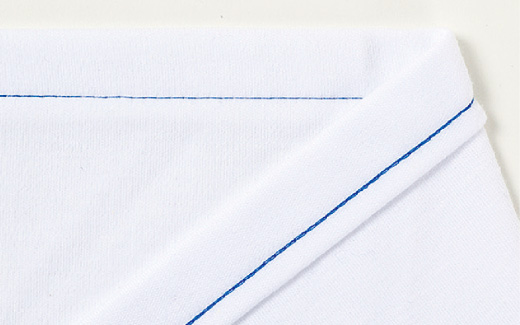

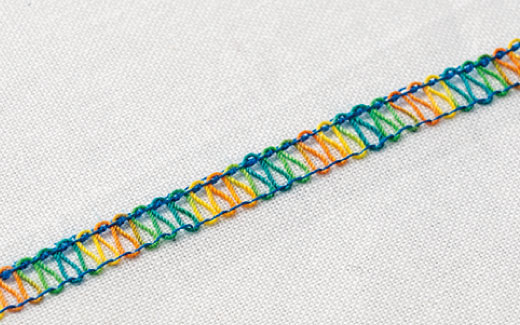

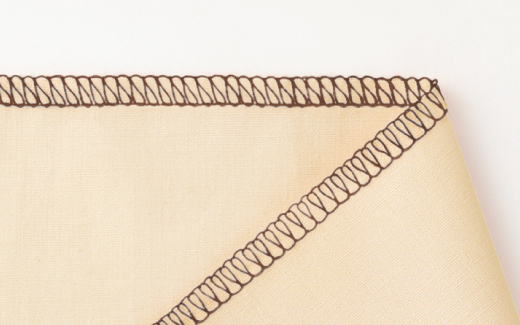

Cover Stitch

Perfect for various applications, such as simple hems, sleeve cuffs and necklines. Because the stitching stretches, it is ideal for stretch fabrics.

4-Thread Cover Stitch

3-Thread Cover Stitch (wide)

3-Thread Cover Stitch (narrow)

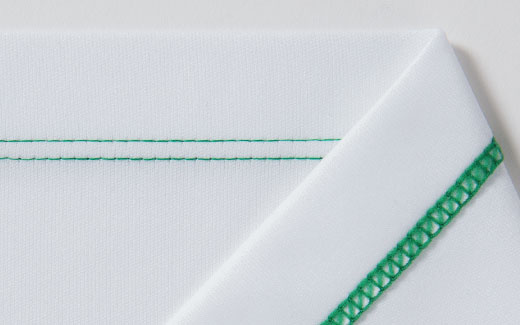

Chain Stitch

Because the lower thread forms a chain on the wrong side of the fabric, the stitch is strong when it is stretched, making it ideal for stitching the waist and side seams of pants. It also does well as decorative stitching for necklines.

Chain Stitch

Overlock Stitches

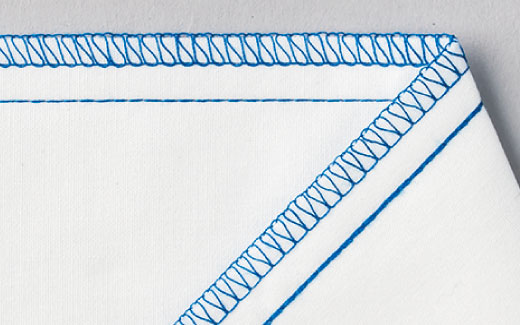

5-Thread Safety Stitch

This is the stitch type that combines 3-thread overlock and chain stitch. This stitch type produces durable seams and is frequently used for joining sides of shirts, for example.

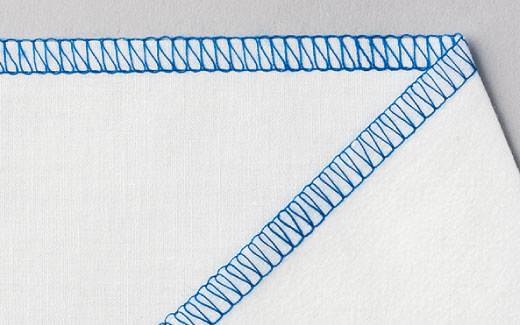

4-Thread Overlock

Uses 2 needles and 4-threads to securely sew together knitted fabrics.

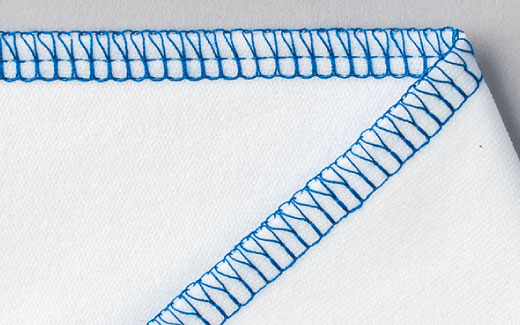

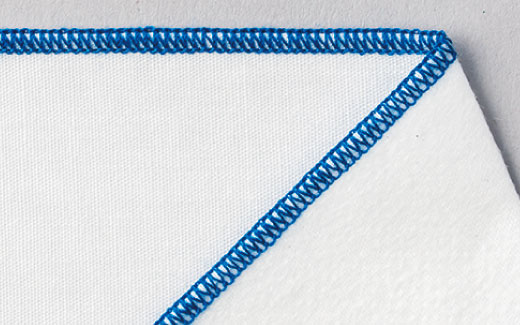

3-Thread Overlock

This basic stitch prevents fabric from fraying.

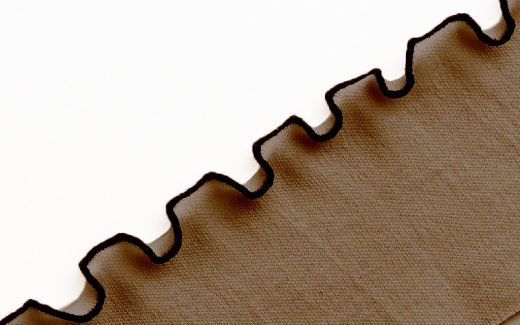

3-Thread Rolled Hem

The fabric edge is rolled, then covered with thread.

3-Thread Narrow Overlock

The fabric edge is rolled, then sewn with very narrow overlocking.

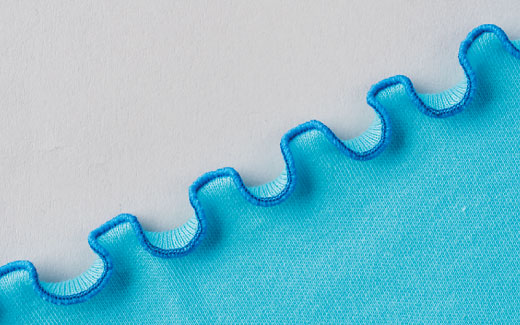

Frill 3-Thread Rolled Hem with Diff. Feed

Uses 3-thread rolled hemming and the differential feed on stretch fabrics to create richly designed pieces.

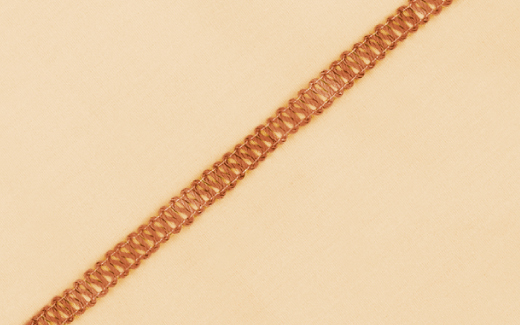

3-Thread Flatlock

This stitch type is used to accentuate clothing, interior goods and small articles.

Since lace thread and wool yarn can be used for sewing the decorative part (as upper looper thread), this seams serve as unique design element of the work.

2-Thread Overcast

Simply sew fabric edges with 2 threads to prevent fraying.

*2-thread converter is included.

Packed with many useful functions!

Cover Stitch Variation

Stitch width can be selected.

For the 4-thread cover stitch, stitch width is 5mm.

For the 3-threadcover stitch, stitch width is 5 mm (wide) or 2.5 mm (narrow).

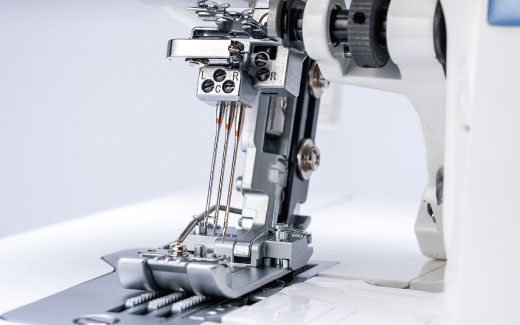

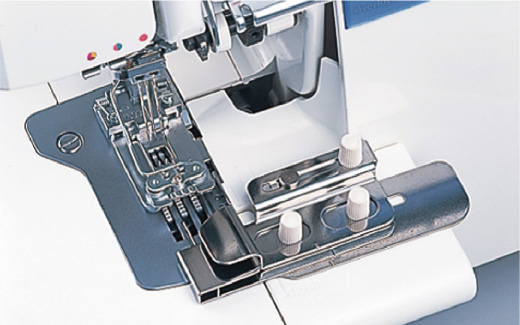

Upper knife releasing system and the auxiliary bed for cover stitch/chain stitch.

Auxiliary bed provided with a scale that serves as a material edge guide and is helpful for sewing.

For cover stitch or chain stitch, the auxiliary bed that is helpful for sewing should be installed. In this case, the upper knife can be released to provide a wider work space.

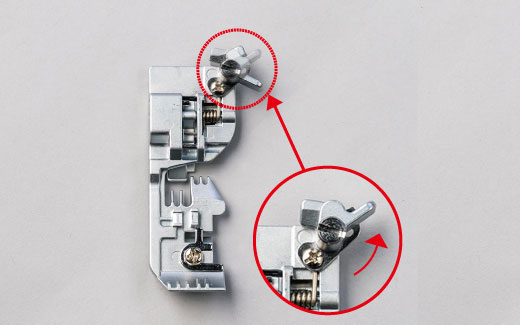

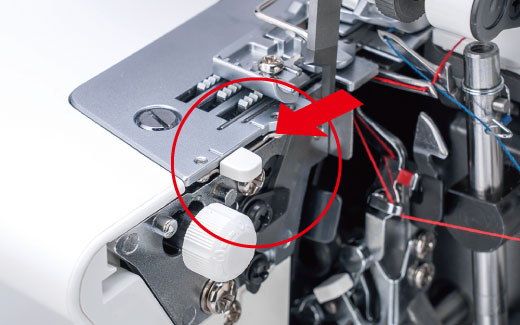

Release of the Presser Foot Pressure (Standard Presser Foot)

When sewing cover stitch, uneven material feed can be effectively reduced by releasing the standard presser foot pressure.

The presser foot pressure is minimized by tilting the presser foot pressure release lever to the rear.

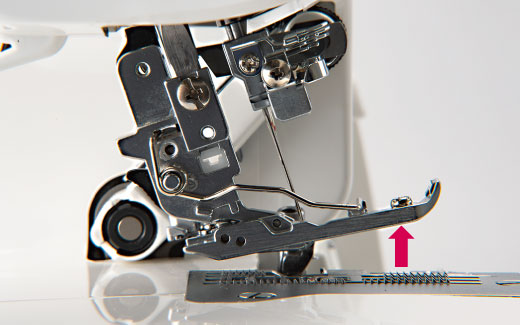

Presser Foot Lifter

The presser foot is higher at its tip in order to allow the fabric to easily be inserted at the start of sewing. In addition, raising the presser foot lifter to the first position raises the presser foot 6 mm.

Further raising the presser foot lifter raises the front of the foot is automatically lifted. This allows you to easily insert thick layers of fabric, for example, when attaching ribbing, under the presser foot.

Adjustable Stitch Length/Differential Feed

Stitch length can be adjusted externally with ease even during sewing by means of the stitch length adjustment dial .

Elastic materials such as knit fabrics and georgette can be finished beautifully by adjusting the differential feed adjustment knob.

Differential feed can be adjusted even during sewing.

(Up) Stitch length adjustment dial

(Down) Differential feed adjustment dial

Stretchy fabrics

Materials that stretch easily such as knit fabrics can be finished beautifully using shirring stitch.

Crinkly fabrics

Materials that are likely to cause stitch gathering can be finished beautifully using stretching stitch.

Other Useful Features

Lay-in Type Thread Tension Slots

Simply raising the presser foot and passing thread straight through the slot threads the tension disc.

Even thick thread is easy to thread.

Slit-Type Molded Looper Threading Paths

Since troublesome threading of the thread take-up lever is no longer required, the machine head can be threaded with ease only by passing the thread along the groove.

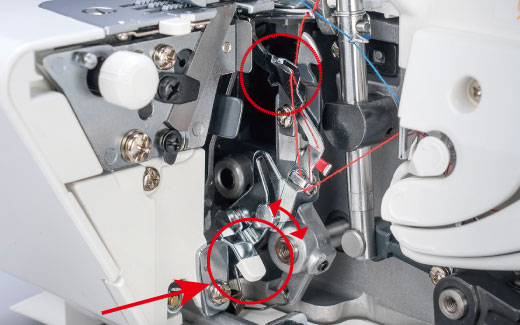

Lower Looper Threader

Threading the lower looper can easily be done by operating a lever.

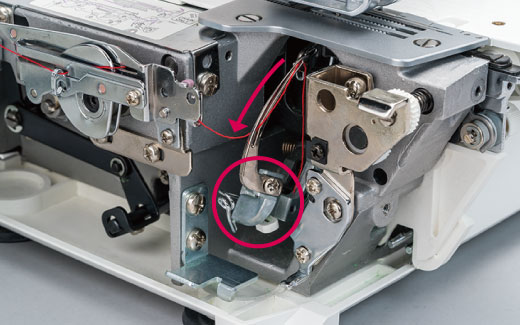

Automatic Rolled Hemming

Simply pulling a lever toward you easily switches the machine to rolled hemming.

Threading of the Chain Stitch Looper

The looper can easily be threaded since it can be lowered at the press of a button.

LED Light

The workspace is brightly illuminated. The long-life, energy-efficient lights will not heat up, even after a long period of use.

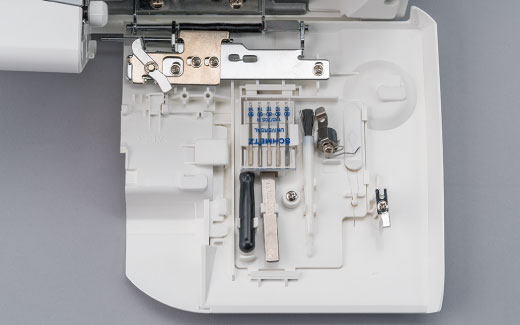

Accessory Storage

Accessories such as tweezers and a small screwdriver can be stored inside the looper cover.

Other Features

● 3-step adjustment of the presser foot pressure

● Exterior thread cutter

● Safety mechanism that prevents the machine from running even when you depress the foot controller with the looper cover left open

タブコンテンツ2(オレンジ線下から)

SPEC / ACCESSORIES

| Dimensions | 300 (W) x 260 (D) x 290 (H) mm |

| Weight | 9.0kg |

| Sewing speed | Max. 1,500spm |

| 4-Thread overlock | ✓ |

| 3-Thread overlock | ✓ |

| 2-Thread overcast | ✓ |

| Rolled hem | ✓ |

| Narrow overlock | ✓ |

| Frill 3-thread rolled hem with diff. feed | ✓ |

| 3-thread flatlock | ✓ |

| Interlock | ✓ |

| Chain stitch | ✓ |

| 4-Thread cover stitch | ✓ |

| 3-Thread cover stitch | ✓ |

| Number of needles | 1/2/3 Needles |

| Needle | SCHMETZ 130/705 H or JLx2 |

| Number of threads | 2/3/4/5 Threads |

| Differential feed ratio | 0.7-2.0 Ratio |

| Easy threader | - |

| Lower looper threader | ✓ |

| TWA (Tweak Width Adjustment) | - |

| Presser foot pressure adjustment | 3 steps adjustment |

| Micro-lifter | - |

| Automatic rolled hemming | Automatic rolled hemming lever |

| Retractable upper knife | ✓ |

| 2-Thread converter | ✓ |

| Thread cutter | ✓ |

| Ajusting cutting width | ✓ |

| Safety design | ✓ |

| Light | LED |

| Presser foot lift (1 step/2 steps) | 6mm + front up |

| Stitch length | 1-4mm |

| Stitch width | (Standard) Left needle: 7-9mm Right needle: 5-7mm Rolled hem: 2mm Chain needle (right needle): 10-12mm Cover stitch: 2.5/5mm (For limited area, /CE/CE5/SAA/IT) Left needle: 5-7mm Right needle: 3-5mm Rolled hem: 2mm Chain needle (right needle): 8-10mm Cover stitch: 2.5/5mm |

| Magnet Needle Tray | - |

| Waste collector | ✓ |

| Knee Lifting Lever | - |

| Operation support | YouTube |

| Accessories | Needle set 130/705H(SCHMETZ) Small screwdriver Tweezers Upper looper converter Needle threader Brush/Needle inserter Electronic foot control Oiler Nets Lower knife Spool caps Accessory bag Dust cover Large screwdriver Cover/chain stitch extension plate Cover stitch presser foot Waste collector Spool holder Needle set JLx2 (3xNo.80) Instruction manual |

OPTIONAL PARTS

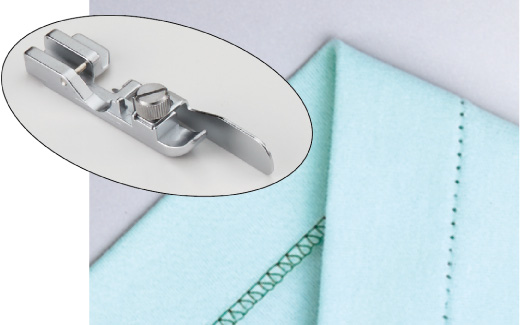

Blind Stitch Presser Foot

Universal Blind Stitch Presser Foot

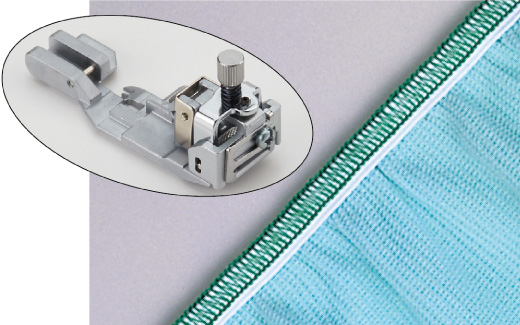

Elasticator Presser Foot

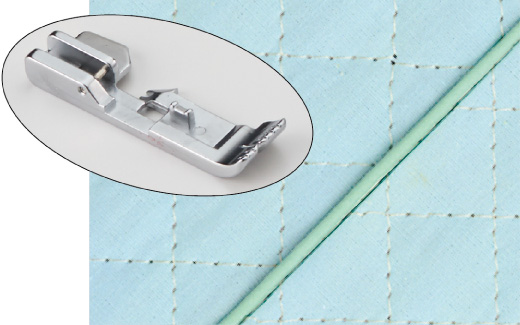

Cording Presser Foot

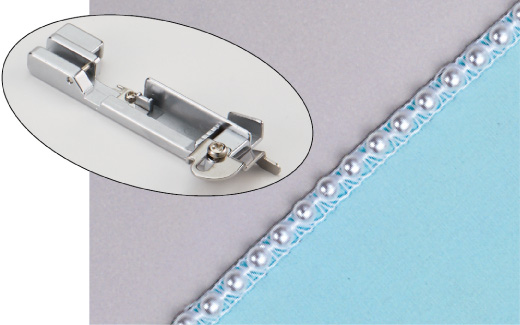

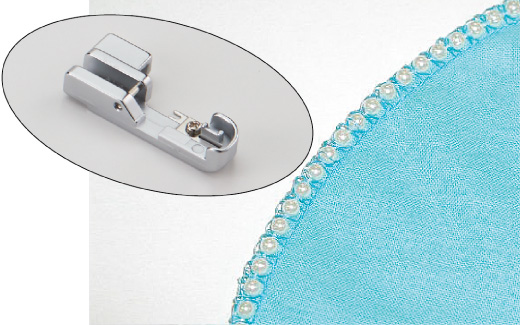

Beading Presser Foot

Curved Beading Presser Foot

Piping Presser Foot

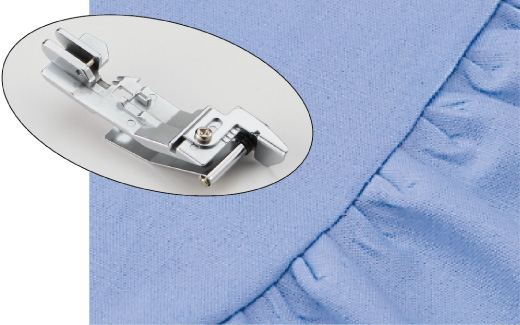

Gathering Presser Foot

Hemmer guide (for cover stitch)

タブコンテンツ3(オレンジ線下から)

STITCH PATTERNS

4-Thread Overlock

Uses 2 needles and 4 threads to securely sew together knitted fabrics.

3-Thread Overlock

This basic stitch of overlock machines prevents fabric from fraying.

2-Thread Overcast

Simply sew fabric edges with 2 threads to prevent fraying.

3-Thread Rolled Hem

The fabric edge is rolled, then covered with thread.

3-Thread Narrow Overlock

The fabric edge is rolled, then sewn with very narrow overlocking.

Frill 3-Thread Rolled Hem With Diff. Feed

Uses 3-thread rolled hemming and the differential feed on stretch fabrics to create richly designed articles.

3-Thread Flatlock

Use this stitch as an accent on clothes, interior items and accessories.

Interlock / 5-Thread Safety Stitch

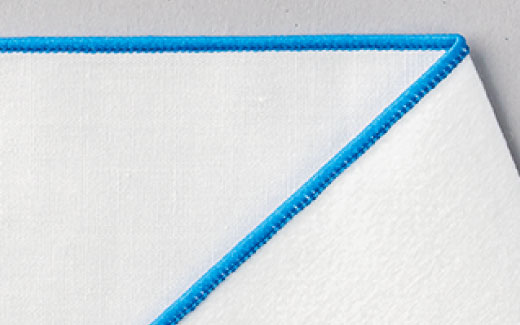

4-Thread Cover Stitch

3-Thread Cover Stitch (wide)

3-Thread Cover Stitch (narrow)